Your trusted partner for food testing

Our food testing laboratory is built to support regional and enterprise food manufacturers. We have a robust portfolio of assays, stringent quality and safety standards, and a customer-centric approach.

Trusted by leaders in food manufacturing

Our commitment to quality

Our accredited status means that our Quality Management System and in-scope analytical methods meet the stringent requirements of an internationally recognized standard of quality for testing laboratories in the Food and Pharmaceutical industry.

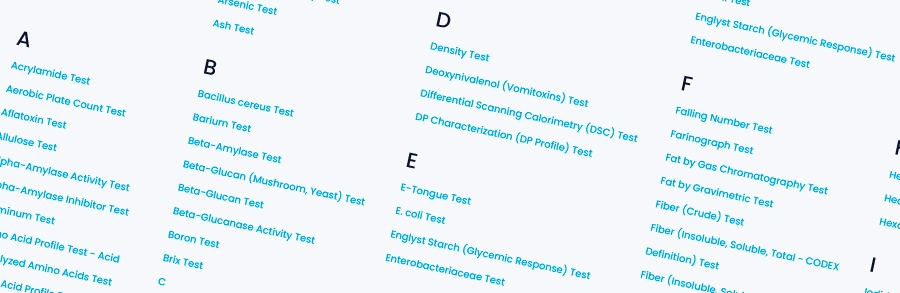

Our food testing services

Our testing portfolio offers hundreds of assays guaranteed to provide quality data; ensuring your testing goals are met.

Create a NLEA Nutritional Label

Ensure quality and meet labeling requirements with Medallion Labs

Shelf life testing

Maintain the integrity of food safety, quality and customer experience

Improve food product quality

Create food with more nutrition, all while still delivering in taste

Verify food fortification levels

Check the levels of vitamins and minerals in your food

Calibrate my factory equipment

Identify where process variability may exist in your manufacturing process

Measure carbohydrate categories

Tests to identify and measure specific carbohydrates in your food

Medallion Labs

Food testing services, the Medallion Labs way

Experience white glove customer service, priority processing and discounts that will save you time and money with Medallion Labs.

A food testing program designed with mid-market and enterprise food and ingredient companies in mind.

Frequently asked questions

Medallion Labs is anISO/IEC 17025accredited testing laboratory. Our accredited status means that our Quality Management System and in-scope analytical methods meet the stringent requirements of an internationally recognized standard of quality for testing laboratories in the Food and Pharmaceutical industry. Our full scope and certificate of accreditation can be accessed in the About Us section of our website. You can also obtain the information from our accrediting agency’s website:a2la.org– certificate numbers 2769.01 and 2769.02.

While our sales and customer service team are happy to answer general testing questions, consultations typically start at a rate of $250 per 30 minutes regarding the interpretation of reported test results or questions about our test methods. We cannot consult on regulations, tolerance limits, or claims.

We make every effort to keep our methods and detection limits up to date according to the latest standards and qualifications. If you have any questions regarding the limit of detection/quantification or method references, please contact our Customer Service team at 1-800-245-5615.

Our standard turnaround time is 10 business days for most assays. There are some assays that require a longer turnaround time. We also offer a RUSH service that is half the time of the standard turnaround time of the assay at double the cost of the assay. A few assays that we provide cannot be rushed due to the nature of the test. Please check the specific assay you are interested in regarding the ability to RUSH the turnaround time.

At Medallion, we try to offer the most sophisticated and current testing capabilities, and strive to keep our website up to date with our recent test offerings. If you do not see the analysis you require, please contact our Customer Service team at 1-800-245-5615. If we cannot run the assay you need, we will do our best to recommend you to another lab that can fulfill your request.

Medallion Labs, a division of General Mills, offers multiple areas of expertise for analytical testing and product evaluation for the food and ingredient industry. Our areas of expertise include Chemical Analysis, Nutritional Analysis, Food Safety, Shelf Life Studies, Microbiology, Specialty Fibers, Physical Testing, Allergen Testing, as well as Product Evaluation (which includes Product Performance and Sensory Evaluation) and Technical Consulting/Method Development. Our methods are developed for the testing of food products and ingredients.

Let’s Get to Work!

Submit your order online and ship your samples today. If you have questions, we are always here to help.

Medallion Labs

A food testing program designed with mid-market and enterprise food and ingredient manufacturers in mind.